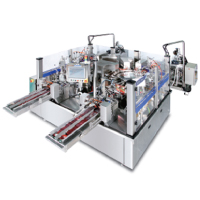

R8Q – 110, 135 Quadro

Standard and optional features available:

- PLC control with touch screen operation

- Two rotary tables on a single platform for high speed operation up to 180 bags / minute

- Long durability welded steel frame

- Washdown structure (IP65)

- Compact design with small footprint

- Easy access rotational touch screen

- Production parameter memory incl. gripper size, machine speed, sealing temperature, filling volume.

- Pouch presence detection – no filling, no sealing

- De-aeration with wire guide or push bars

- Steam/gas flush

- Automatic deoxidizer feeding station

- Product filling – can be integrated with weighing scales/cup conveyor

- Two step sealing process guarantees clean sealing, cooling station for liquid product

- Encoder controlled inkjet printer for accurate printing position at high speed

- Mechanical zipper opener

- Available to accommodate 2 different products at the same time

| Model | R8Q-110 | R8Q-135 |

|---|---|---|

| Max. speed per minute (Idle cycle) | 120 | 120 |

| Bag gripping range (mm) | 75-110 | 90-135 |

| Max. bag length (mm) | 320 | 320 |

| Electrical requirements | 220-430V, 3-phase, 50/60Hz | |

| Compressed air | 600 L / min @ 6 bar | |

Ready to eat foods, solids in the sauce or vegetable meat mixes Rotary pouch machine integrated with cup conveyor, cup feeder, multi-head weighing unit.

| Solid in the sauce product examples: | Common Options / Machine option | Filling option | Product conveying option |

|---|---|---|---|

|

|

|

|

– Click for PDF brochure.

– Click for PDF brochure.